SAP Concepts

Every

organization’s Sales is structured in a certain way. This structure needs to be

represented in SAP based on pre-defined organizational elements and combine

them in a pre-defined way. This method of representing all the different

organizational elements of the company in a structured way is called Enterprise

Structure. Organizational elements or Org Units for short are a system

representation of an actual company organizational unit. For example, an org

unit in real life could be a particular product division, or a Sales Office in

Seattle, or a manufacturing plant in Boston or a warehouse in Alabama. The

following picture shows how an enterprise structure is created in SAP.

Instead

of discussing the text book definitions of these organizational units, let’s

take a company in real life and discuss the same. However, please do note the

cardinality. For example, a company can be linked to multiple company codes as

shown in the beginning of the picture above. Let’s take the example of General

Electric Healthcare ( or GE Medicals ) and discuss the enterprise structure in

detail. We have taken GE just as an example, and this enterprise structure in

no way represents GE’s internal structure. In fact, GE Healthcare does not even

use SAP as its ERP.

Before

discussing the same, let’s look at another pictorial representation of the same

picture as above – but with GE’s org units.

Company

GE

Medicals is the name of the company. This company has presence across the

world. And when GE Healthcare declares profits in the US, it is not just

including the US Company but the entire world. In SAP parlance, GE Medicals is

a Company.

Company Code

GE

Medicals in the US will be run through a legal entity. A company code is an

entity that has to report its financials to the government on a timely basis.

For example an incorporated entity can be called a company code. In this case,

GE Medicals in the US is being called as a legal entity.

Sales

Organization

Since

the company has presence across the US, there will be sales organizations

across the United States responsible for selling goods. For example, the

Western division is responsible for selling goods in the Western states. The

same organization is also responsible for handling returns, credits, availability

of materials etc.

Distribution

Channel

Just

as the name speaks, a distribution channel is the sales channel through which

products are distributed. In this case, the medical equipment could be sold

through the direct channel or through an agency. Each of them will be

represented as a distribution channel. A more common example could be Retail or

Wholesale.

Division

Division

is purely related to the product/service we are selling. Its a grouping of our

products. For example all different types of X-Ray machines would fall under

the X-Ray division.

Sales Office

The

western division of the company might be having multiple sales offices in California.

For example there could be one in the bay area and another in Los Angeles

Sales Group

Each

sales office contains multiple sales groups who have a fixed set of

responsibilities. It could be based on the products that they sell or the type

of sales that they perform or the role they play in the actual sale. For

example, a sales group could be responsible for selling consumables used in the

X-Ray while the field-apps will be responsible for selling the software used in

the machines.

Plant

A

plant is where goods are manufactured. Sometimes, you might not even

manufacture anything – Just trade goods. Still you would need a plant. So a

plant could be a physical or virtual place where goods are manufactured or

stored at a high level. For example, there could be a plant in New Jersey.

Storage

Location

Each

plant could be associated with multiple storage locations – A place where goods

are stored before being sold. For example, the new jersey plant could have

storage locations in Edison and Iselin.

Warehouse

A

warehouse is an extension of the storage location. While a storage location

represents a location where goods are stored, a warehouse goes much further and

describes how the goods are sold, the topography of the storage, storage

conditions etc. Goods can still be sold without using Warehouse Management, but

a sales cannot happen without a storage location.

Sales Office

A

combination of the sales organization, distribution channel and division is

called the sales area.

Sales

Organization + Distribution Channel + Division = Sales Area

Configuration

The

configuration for the enterprise structure is very simple. The Menu path is [

SPRO -> IMG -> Enterprise Structure ]

SAP SD –

Document Flow

Introduction

Each

document is either created on its own or created with reference to another

document. For example, a sales order can be created with reference to the

quotation, whereas the quotation itself can be created on its own. The

following diagram illustrates all the possible document flows in SAP.

Transaction Codes Tip:

The transaction codes can for the respective document flow configuration

transactions can be easily identified by visualizing the picture below. If ‘A’

stands for Sales documents , ‘L’ stands for Deliveries and ‘F’ stands for

Billing documents, then the transaction for configuring the Sales document to

the delivery document is VTLA. So it is VTXY with X as the target document and

Y as the source document.

Let’s

see some examples of different types of document flow using examples of

standard commonly used sales scenarios.

Sales-to-Sales Document Flow:

For example you can create a Sales Order from a Contract or a Quotation.

Sales-to-Delivery Document Flow:

For example you can create a standard or a rush delivery from an order.

Similarly you can create a consignment delivery from a consignment.

Delivery-to-Billing Document Flow: A standard invoice is created with reference to a

delivery.

Billing-to-Billing Document Flow: Invoice cancellations are typically done with respect

to the original invoice.

Billing-to-Sales Document Flow:

In case of debit memo requests or credit memo requests, the original invoice is

used as a reference document.

Without

going further, let’s dig a little deeper into the concept of “Reference”.

Whenever we mean a document is referencing another document, this means that

information is copied over from the previous document into the subsequent

document. What is the need for information to be copied over..? There are many

reasons for this. For example, this reduces burden on the person entering the

subsequent document. Also, this ensures that information is accurately copied

over without mistakes.

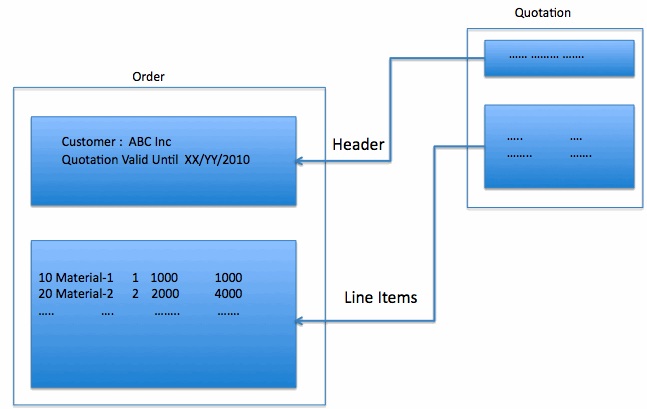

Let’s

take an example. A customer has called us and asked for a quotation. Our sales

force has responded with a quotation.

The

quotation could contain a bunch of data like who the customer is, his/her

internal number with us, date of the quotation, date valid until, prices,

discounts, surcharges, taxes, materials, quantity etc.

The

customer then places an order referring to the prices in the quote.

During

the process of creating the order referring to the quotation a bunch of date

needs to be copied. Example data could include prices, customer data, materials

and quantity, discounts given etc. In order to do these efficiently copy

control routines are used. Copy control configuration is also part of the document

flow.

Some of the

main SAP SD transactions are:

VA01

– Create Customer Order

VL01N

– Create a Delivery

VA03

– Display a Order

VL02N

– Change Customer Delivery (F20 is to post a good issue)

VA05

– List Orders

VF01

– Create a Invoice

The

Order to Cash flow roughly follows the following sequence -

A

customer orders some items from your company by creating a sales order

Your

company decides to deliver the items ordered by the customer.

This

is recorded by creating a outbound delivery document

Once

the items are available for sending to the customer, you post goods issue which

reduces your inventory and puts the delivery in transit. This will create a

material document.

You

will post goods but the material document created will be stored in tables.

You

will then create shipment document to actually ship the items.

You

finally create a sales billing document.

This

will have a corresponding accounting document created that will be in different

tables.

When

customer pays to your invoice, it will directly hit your AR account in FI.

Master Data in Sales and Distribution

Use

SD is organized according to sales organization, distribution channel and division. A combination of these three organizational units forms the sales area.

The following graphic displays these organizational elements.

In sales organization 1000, sales and distribution

transactions can be carried out through all distribution channels and for all

divisions.

In sales organization 2000, products of both

division 01 and division 02 are only sold through distribution channel 10.

In sales organization 3000, only products of

division 01 are sold, and only through distribution channel 10

Use

The organization in Sales is represented by the elements sales office, sales group and salespersons. The following figure displays a sample organization in business development and sales.

Geographical aspects of the organization in business development and sales are defined using the term sales office. A sales office can be considered as a subsidiary. A sales office establishes contact between the firm and the regional market.

Sales group

The staff of a sales office may be subdivided into sales groups. For example, sales groups can be defined for individual divisions.

Salespersons

You can maintain personnel master records for sales representatives in your company. In the personnel master record, you assign the salesperson to the sales office and the sales group.

You can also enter the system user name of the sales person. This allows mails to be sent to the salesperson (define the partner function for sales personnel in the sales document).

Organization in Shipping and Transportation

Use

Independent organizational entities, such as shipping points, are responsible for scheduling and processing deliveries to customers, as well as replenishment deliveries to your own warehouses.

A delivery is always carried out by one shipping point only. The shipping point depends on the following criteria:

- Delivering

plant

- Type

of shipping (for example, train, truck)

- Loading

equipment necessary

Shipping points can be subdivided into loading points. For example, ramp 1, ramp 2 and ramp 3 belong to the shipping point Forwarding depot.

The following figure displays a possible organization in shipping.

The transportation planning point is an organizational unit in Logistics, responsible for planning and processing transportation activities.

It organizes the responsibilities in a company, e.g. according to shipment type, mode of transport or regional departments.

Integration

The shipping point is assigned to a plant.

Loading points are assigned to shipping points.

Link to Materials Management Structure

The plants allowed for sales are determined for each sales organization according to the distribution channel, so that a sales organization can sell goods from several plants. A plant can be assigned to different sales organizations. All of these sales organizations can sell from that plant.

You can differentiate further between the plants belonging to a sales organization from the sales view using the distribution channel. For certain plants within a sales organization, the distribution channel "sales from plant" is allowed, but not for others.

The following figure shows an assignment of sales organizations and plants.

Sales organization 1000 sells from plants 1000 and

2000

Sales organization 2000 only sells from plant 2000

Sales organization 3000 only sells from plant 3000Customers and Business Partners

Definition

A company deals with different natural and legal persons during business transactions: A customer orders goods from your company. A forwarding agent might deliver goods to the customer. An employee within the company processes the business transactions. All roles a natural or legal person can assume are represented by business partners in the SAP R/3 System.

Business partners

A company has contact with its business partners, who are customers and vendors. Data on each of these and on the company's personnel is stored in a separate master record.

Customers

The term "customer" is used to define all customers to whom the company has contact. The term "vendor" is used to define all business partners who carry out a delivery or a service for the company. A business partner can be a customer and a vendor at the same time if, for example, your customer also supplies goods to you. In this case, both a customer master record and a vendor master record must be created for the business partner. You can create a link between the master records by entering the vendor number in the customer master record and the customer number in the vendor master record.

Vendors

Data on business partners who are vendors, for example, forwarding agents, is managed in the vendor master record. If a vendor is also a customer, a link can be created.

Personnel

Data on employees of your own company, for example, sales personnel or clerical staff, is managed in the personnel master record. Data on each employee can be managed by his or her personnel number.

Only the personnel department of your company is authorized to create a personnel master record, using Human Resources (HR). The personnel department of your company manages the personnel numbers of the employees. If HR is not used in your company, you can create a personnel master record yourself for employees in sales and distribution.

Business Partner Master Data Structure

Use

You enter data on business partners with whom your company has a business relationship in master records. Master records contain all data necessary for processing business transactions. This is known as master data.

If you enter all master data, you spend less time processing business transactions because the system proposes the master data in these transactions.

Financial Accounting and Logistics use master data. General data and data relevant to both departments is stored in shared master records to avoid duplication.

Features

You can create and change master records using groups of data that differ in the level of detail.

Master records for business partners who are customers or vendors have the following structures:

Customer Master Records

Vendor Master Records

Use

Use partner functions to define the rights and responsibilities of each business partner in a business transaction. You assign partner functions when you create a master record for a business partner.

Features

The following are examples of partner functions that are defined in the standard R/3 System:

Partner functions for partner type customer

- Sold-to Party

Contains data on sales, such as the assignment to a

sales office or a valid price list

- Ship-to Party

Contains data for shipping,

such as unloading point and goods receiving hours

- Bill-to Party

Contains the address and data

on document printing and electronic communication

- Payer

Contains data on billing

schedules and bank details

Partner functions for partner type vendor

- Ordering

address

- Invoice

presented by

- Goods

supplier

- Alternative

payee

Partner functions for other partner types, for example, personnel (HR

master records)

Employee responsible

You can use this partner function, for example, to

assign a buyer within your company to a vendor.

Consumers

Use

A consumer is a natural, private business partner with whom you have a relationship involving the transfer of goods and services. You create customer master records for business partners who are consumers.

Products and Services

Use

Products and services are combined in the SAP R/3 System under the term material. All information necessary for the management of a material and its stocks, as well as its use, is maintained in the so-called material master record. This includes, for example, data on purchasing, on sales and on storage.

Different company areas and SAP modules access the material master records, which therefore must meet a wide variety of requirements. During sales processing, the system repeatedly accesses the material master records. It is one of the basic sources of data for sales processing. The material master record is accessed, for example, in the inquiry, in the quotation and in the sales order. Data in the material master record is also of great importance for shipping and billing. However, the data required for shipping, for example, is not the same as that required for sales or billing.

Material Types

Use

Material types in the SAP standard version are, for example, raw materials, trading goods, semi-finished products, finished products, or services. The material type represents certain features of materials in the system, and has important control functions: the material type is used, among other things, to group field selection functions for a material, or to define the screen sequence, the type of number assignment and number ranges during material master record maintenance. Depending on the material type, company areas maintain different data screens. This screen selection applying specifically to an application is called a "view".

The following are examples of possible material types in the SAP standard version:

- Trading

Goods

- Non-stock

Material

- Services

- Packaging

Material

Trading goods are movable goods intended for commercial exchange. Examples of trading goods are market goods, consumption goods and durable goods. Trading goods are always bought and re-sold by your company. The material master record for trading goods therefore always contains purchasing data and sales data. Trading goods are managed in the SAP R/3 System using the key HAWA.

Non-stock Material

Non-stock material includes materials that are not managed on an inventory basis (for example, small parts such as nails) though physically in stock. Non-stock materials are managed in the SAP System using the key NLAG.

Services

Services are represented and managed in the SAP System as materials. Services are immaterial goods that differ from other goods, particularly in that their production and consumption coincide. Services are generally regarded as non-transportable and non-stockable. Typical services are commercial services, transport services, bank and insurance services, goods from cultural organizations and the mass media, as well as services provided by the public security forces or the education and health sectors.

Since services cannot be stored, a material master record of this material type does not contain inventory data or inventory management data. No fields for gross weight, net weight or unit of weight are included in the basic data for a service, as are for other material types. Services are managed in the SAP R/3 System with the key DIEN.

Packaging Material

This material type includes all materials needed for packaging. For example, boxes or crates. Packaging materials are managed in the SAP R/3 System with the key VERP.

Other Material

Materials which cannot be assigned to any of the standard material types, can be maintained, as "Other material". Thus, besides standard material types (trading goods, finished products, services etc.) you can also create additional material types. When creating such a material, note that a material type must be entered on the first data screen. For standard material types, this entry is not necessary because the material type is selected in the menu.

Units of Measure and Quantity Specifications

Units of Measure

A material can be stored, transported and sold in various units of measure. In the SAP R/3 System, you can therefore define various units of measure which are maintained in the sales and distribution screens. However, you only need to maintain the fields of the units of measure if they deviate from the base unit of measure. If no other fields with units of measure are maintained, the system automatically takes the base unit of measure as a basis for its calculations. You can enter the following units of measure in the sales and distribution screens:

- Base

Unit of Measure

- Alternative

Unit of Measure

- Sales

Unit

- Delivery

Unit

The delivering plant refers to the plant from which the goods are to be delivered to the customer, within a specific sales organization and distribution channel. The plant can be automatically proposed by the system when processing a sales order, if it has been maintained in one of the master records. It can be derived from:

- the

customer/product info record

- the

customer master record of the ship-to party

- the

material master record.

Customer Material Information

Purpose

Data on a material defined for one specific customer is stored in the customer material information records. This data includes

- the

customer-specific material number

- the

customer-specific material description

- customer-specific

data on deliveries and delivery tolerances

Basic Functions in SD

The most important basic functions are:

o

Pricing

o

Availability Check

o

Credit Management

o

Material Determination

o

Output Determination

o

Text Processing

o

Tax Determination

o

Account Determination

No comments:

Post a Comment